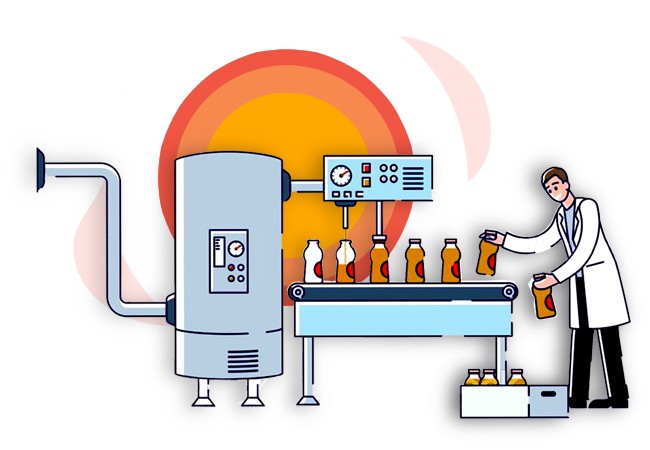

The production process for fruit drinks and beverages involves several steps, including the careful selection of fruits, washing and cleaning, juice extraction, preparation of sugar syrup, the blending of pulp, syrup, and other ingredients, adjusting ingredients as necessary, filling, sealing, and labelling the bottles.

Sound fruit freshly harvested from the fields are sourced for processing.

The fruit is squeezed mechanically to extract pulp.

Various major and minor ingredients are added to pulp and subjected to boiling to obtain the desired characteritics.

The final product is tranfered to PET bottles.

The jam-making process typically involves chopping the fruits and cooking them with sugar and pectin until they form a gel-like consistency. Once ready, the mixture is packed into sterilized jars, and then labelled.

In this process, the fruits are thoroughly cleaned and blanched. Then, they're packed into cans or jars and heated. Finally, the cans or jars are cooled rapidly to maintain the fruits' texture and taste.

In the process of making condiments, the fruits or vegetables are cooked and processed by removing their seeds, followed by grinding. After this, the mixture is cooked again to the desired consistency with sugar, salt, spices, or other flavorings, depending on the recipe. Once, done the mixture is packed and labelled.